Metallurgical Mine

- Categories:Business scope

- Time of issue:2020-08-06 14:47

(Summary description)The demands of metals run through the human development history. In recent years, the increased global population and improved human living standard have increased demands for various minerals year by year.

Metallurgical Mine

(Summary description)The demands of metals run through the human development history. In recent years, the increased global population and improved human living standard have increased demands for various minerals year by year.

- Categories:Business scope

- Time of issue:2020-08-06 14:47

Industry introduction

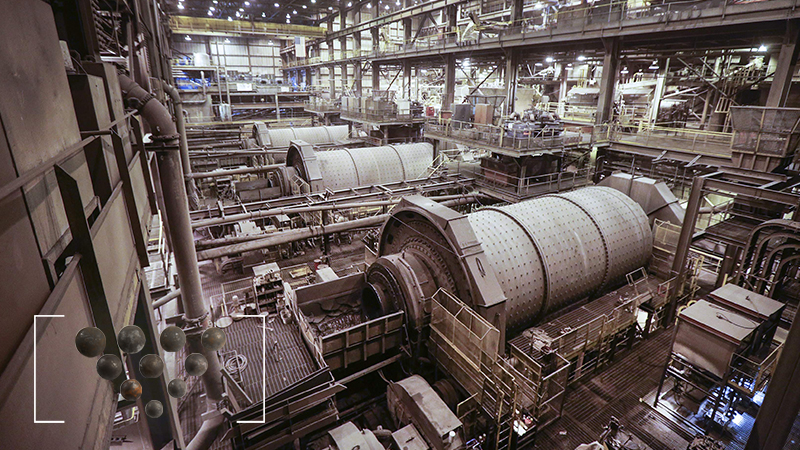

The demands of metals run through the human development history. In recent years, the increased global population and improved human living standard have increased demands for various minerals year by year. With progress of exploitation technology, output of ores increases, but the grades declines. The method to increase ore sources is to make exploitation deeper, which means more costs simultaneously, especially in nonferrous metal mines.

Product application

Grinding balls for ball mills (abbreviated as grinding ballss) are widely used in large-scale gold mines, nickel ore, copper mines and other non-ferrous metal mines at home and abroad, iron ore and other ferrous metal mines, and metallurgical and chemical industries and other precious metal beneficiation industries. They are used in ball mills to crush ores. . It has the characteristics of high hardness, low crushing rate and excellent abrasion, and is favored by users all over the world.

Technical Research and Development

● The grinding balls branch has 4 internationally advanced production lines, 7 industry-leading fully automatic continuous rolling production lines, and 11 professional forging ball production lines, covering all sizes of large, medium and small

● Independent research and development of the pre-heat treatment process for large steel balls

● Use high-precision automatic control with strategic partners' supporting equipment, and implement the proprietary grinding auxiliary system FIT System

● Independently developed and designed 6-inch and 6.25-inch high-hardness steel balls, making a positive contribution to the grinding application field of SAG mills in the world

Honor and Qualification

grinding balls products have passed ISO 9001:2008 quality management system, ISO 14001:2004 environmental management system and OHSAS 18001:2007 occupational health and safety management system certification. And was selected as an approved supplier by RioTinto and Bhpbilliton. [Check more certificates]

Partners

● Co-study with the University of Science and Technology Beijing on determining and process optimization of the solidification end of continuous casting of grinding ball steel

● In-depth cooperation with ME ELECMETAL for grinding balls products for mine ball mills

© 2020 ChangShu LongTeng Special Steel Co.,Ltd 苏ICP备541368851号